LABORATORY COUNTER TOP - WORKTOP

Choosing the appropriate work surface for laboratory is a hard decision since there is lot of factors to be considered. Lab countertops and work surfaces are typically the most harmed area of the laboratory. The right material for the purpose is depending on the type of experiments or the work you conduct daily.

The most important factors to consider are: Chemical resistance, Abrasive resistance, Heat resistance, Impact resistance, Moisture resistance, Bacteria, Type of use, Aesthetics and Cost.

TRESPA TOP Lab

TRESPA worktop is a flat one piece panel based on thermosetting resins, homogeneously reinforced with cellulose fibers and manufactured under high pressure and temperature. It is ideal for laboratory environments. Trespa® products for scientific surface solutions are tested and certified according to international standards in relation to chemical resistance, low emission, food contact and other properties.

EPOXY RESIN

Epoxy Resin is the modern laboratory benchtop material that offers a perfect combination of features and benefits. It is durable, extremely chemical and stain resistant, mechanically strong, easily cleaned and decontaminated and exhibits good fire resistance and fire propagation properties.

Custom made worktops available from 19mm to 25mm thick epoxy sheets

CERAMIC WORKTOP

A blend of clay, quartz, feldspar and other natural products suitably mixed and fired at a temperature of 1240 °C. Unlike other standard worktops ceramic has higher density, lower absorption of liquids and a higher resistance. The glazing of ceramic worktop is specially considered to withstand the aggression of chemical agents normally used in the laboratory applications. During the glazing process, colour pigments are sprayed on the surface and, with the heat process at high temperature; they completely blend together with the ceramic surface and crystallize.

GRANITE WORKTOP

Granite is a type of igneous rock; it is tough and durable and is, therefore, an ideal material for worktops. Granite is much less porous than marble.Granite worktop will be minimum of 19mm thickness .The exposed edges shall be round molded. The stone is naturally quite rough and textured, but when it is ground and polished during the countertop manufacturing process, it takes on a smooth surface with rich luster. Granite is comprised of a many different minerals that give each countertop slab a unique and attractive appearance.

POLYPROPYLENE

Polypropylene worktop has good level of chemical resistance recommended for moisture and wet areas.

Polypropylene countertops are used in a wide variety of applications and specialized labs where high resistance to corrosion is required. Polypropylene is the best countertop material if your operation is acid rich

Custom made worktops available from 3mm thick to 15mm thick Polypropylene sheets backed with 18mm to 36mm plywood worktops and hot melt glued PVC edging.

SOLID SURFACE (ACRYLIC)

Solid surface is an ideal material for commercial and residential application such as kitchen, reception, etc. The fabrication advantages are flexible, can be cut, shaped, moulded, and formed in to 3Dshapes.

Solid surface worktops are made of 12mm thick solid surface sheets backed with 18 to 36mm plywood with integrated backsplash and downturn

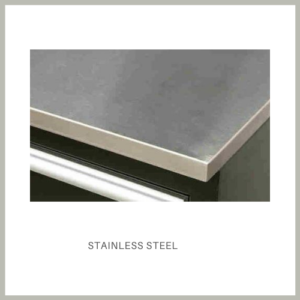

STAINLESS STEEL

Stainless steel worktops are basically inert to most of the acids / alkalis released by cooked foods, vegetables, additives, etc. Stainless steel is easy to clean and with only a minimum of maintenance.. Stainless steel is extremely durable, stain resistant, will not chip or fade, easy to clean, and 100% recyclable.

The stainless steel worktops are made of 1.2mm thick 304 or 316 Grade stainless steel sheet backed with 18mm to 36mm plywood and 100mm high integrated backsplash

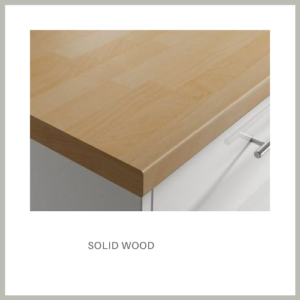

SOLID WOOD

Solid wood worktops are for mechanical / workshop benches where physical activities are more on the work surface. Solid wood worktops will provide a natural beauty to your work area that is hard to replicate. One of the main advantages of a wooden worktop is that unlike other surfaces which age over time and usage, wood does not lose its original splendor. Wooden worktops are available in different thickness and finish.

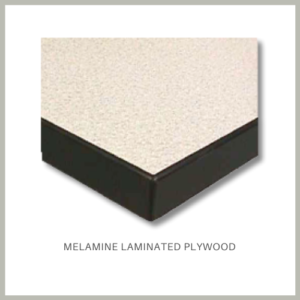

MELAMINE LAMINATED PLYWOOD

Laminated plywood is mainly using for office and dry work areas, computer lab etc. Plywood worktop made of 24 mm BWP (Boiled Water Proof) plywood laminated with 0.9 mm thick High Pressure Laminate on both sides. The lamination is done with hot press with minimum of 90 tones pressure. All worktops shall have 3mm thick hot melt glued PVC edging and 100mm glued back splash for wall benches.